Opel Corsa Engine: Common Issues and Exactly How to Fix Them

Opel Corsa Engine: Common Issues and Exactly How to Fix Them

Blog Article

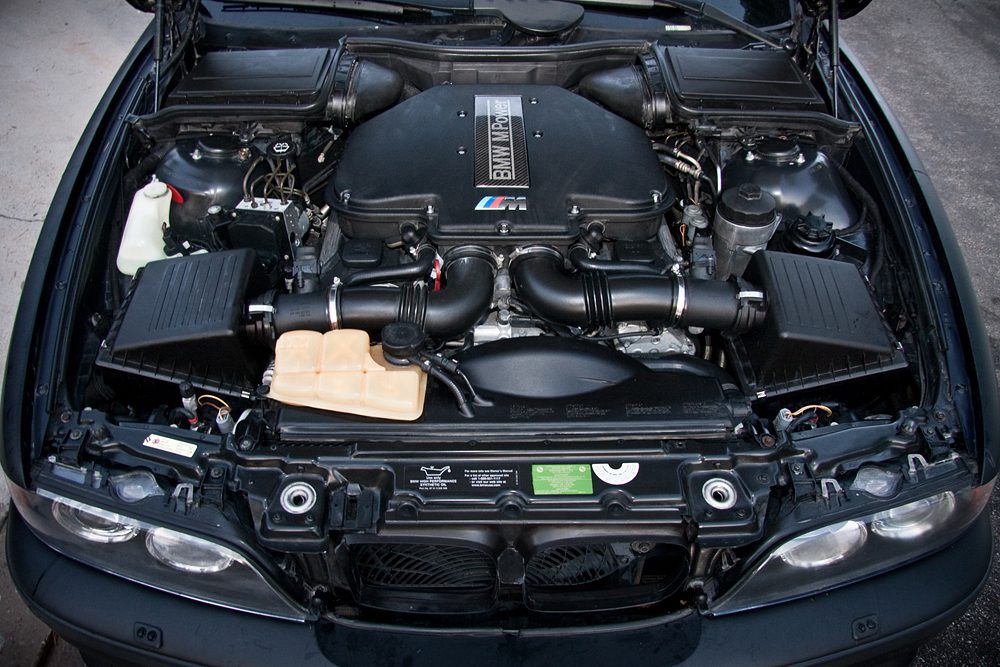

Checking Out the Inner Operation of a Compact Car's Engine System

As vehicle drivers, we usually consider granted the elaborate processes that occur within the boundaries of our vehicle's engine system. The portable yet complicated equipment that propels us ahead is a wonder of design accuracy and sychronisation. From the regulated surges in the combustion chamber to the meticulous timing of gas injection, every part plays an important role in the smooth procedure of the engine. In this expedition of a small vehicle's engine system, we will certainly decipher the inner workings of this mechanical symphony, losing light on the secrets that drive us onward on our day-to-day trips.

Combustion Refine Summary

The combustion procedure in a compact lorry's engine system is a critical mechanism that successfully converts gas right into power to power the car. This procedure occurs within the combustion chamber of the engine, where fuel and air mix, stir up, and produce regulated explosions. The burning procedure contains 4 major phases: intake, compression, power, and exhaust.

During the consumption phase, the piston relocates downward, pulling in a mixture of air and fuel right into the burning chamber. The following phase, compression, includes the piston relocating upwards, compressing the air-fuel combination to enhance its potency. Ultimately, in the power stage, the ignition system sparks the pressed mixture, causing a rapid growth of gases that forces the piston pull back. This downward movement creates the power required to drive the vehicle. In the exhaust phase, the burned gases are expelled from the burning chamber through the exhaust shutoff, preparing the chamber for the following cycle. This cyclic burning procedure is essential to the procedure of a small vehicle's engine system, making certain effective power conversion for propulsion.

Piston and Cylinder Interaction

The piston's precise fit within the cyndrical tube is vital for maintaining optimal compression and preventing energy loss throughout burning. Limited clearances between the piston and cyndrical tube wall surfaces make sure effective sealing, enabling the piston to relocate efficiently without allowing gases to leakage past. Proper lubrication is also crucial to reduce rubbing and use between these elements, enhancing durability and efficiency.

Additionally, the design and materials made use of in manufacturing the piston and cyndrical tube effect engine efficiency and durability. Modern engines often utilize lightweight yet sturdy materials like aluminum alloys for pistons and cyndrical tube liners to decrease inertia and enhance thermal efficiency. Generally, the harmonious interaction between the piston and cyndrical tube is basic to the engine's performance and overall efficiency.

Fuel Shot System Performance

Gas shot systems in portable automobile engines play a critical duty in exactly supplying fuel to the burning chamber for controlled and effective ignition. The gas shot system operates by injecting gas into the combustion chamber at the optimal moment during the engine's operation (opel corsa engine). This specific timing makes sure that the fuel blends evenly with the air for proper burning, bring about enhanced gas effectiveness and decreased emissions

There are mainly two sorts of fuel shot systems used in portable automobile engines: port gas injection (PFI) and straight gas injection (DFI) PFI systems infuse gas right into the intake port before the consumption shutoff, while DFI systems inject fuel straight into the combustion chamber. Both systems have their advantages, with DFI using better fuel atomization and PFI offering an extra affordable solution.

Understanding Engine Cooling Systems

Efficient operation of a small automobile's engine depends greatly on the efficiency of its cooling mechanisms. Engine cooling is important to stop overheating, which can cause serious damage and decreased performance. The cooling system in a portable car usually includes numerous components working together to manage the engine temperature level. One crucial component is the radiator, which makes use of coolant to take in warm from the engine. As the hot coolant flows with the radiator, it launches warmth into the air, cooling off prior to going back to the engine. The water pump circulates the coolant through the engine and radiator, guaranteeing a regular circulation to regulate temperature. In addition, the thermostat aids regulate the coolant flow to maintain optimum engine temperature level. Some lorries additionally have cooling fans that trigger when added air conditioning is needed, such as during rush hour or warm weather. Recognizing these engine cooling systems is vital for preserving the efficiency and durability of a portable lorry's engine system.

Exhaust System Parts Explained

The optimal performance of a small automobile's engine cooling systems relies on a complementary system referred to as the exhaust system, which comprises various essential elements for making certain reliable discharges and engine performance. The exhaust system consists of elements such as the exhaust manifold, catalytic converter, muffler, and tailpipe. The exhaust manifold gathers exhaust gases from the engine's cyndrical tubes and paths them to the catalytic converter. The catalytic converter then More Bonuses converts hazardous contaminants in the exhaust check that right into much less unsafe discharges before releasing them with the muffler and tailpipe.

One crucial part of the exhaust system is the oxygen sensing unit, which keeps an eye on the oxygen levels in the exhaust gases to aid regulate fuel usage and make sure optimal engine efficiency. opel corsa engine. Furthermore, the resonator might be existing in some exhaust systems to lower sound levels. Generally, the exhaust system plays an important function in keeping engine effectiveness, decreasing dangerous discharges, and ensuring a quieter driving experience for compact automobile proprietors

Final Thought

In conclusion, the portable automobile's engine system is an intricate combination of elements that work together to facilitate the combustion process, convert gas right into energy, and remove waste gases. Recognizing the internal operations of the engine system, including the piston and cyndrical tube communication, fuel injection system, engine air conditioning systems, and exhaust system elements, is essential for keeping optimum performance and efficiency of the car.

The combustion process in a compact lorry's engine system is a vital device that efficiently converts gas right into energy to power the vehicle.Fuel shot systems in portable lorry engines play a vital role in exactly delivering gas to the burning chamber for controlled and efficient ignition.There are primarily 2 types of fuel injection systems made use of in compact car engines: port gas injection (PFI) and straight gas injection (DFI) Comprehending these engine cooling systems is crucial for preserving the performance and durability of a small vehicle's engine system.

The optimal performance of a portable lorry's published here engine air conditioning systems depends on a complementary system known as the exhaust system, which consists of various essential parts for guaranteeing efficient discharges and engine efficiency.

Report this page